Production

Printing

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One colour is printed at a time, so several screens can be used to produce a multi-coloured image or design.

Water transfer printingis a surface decorating process with which elaborate graphics – such as wood grain, carbon fiber, camouflage, geometrical designs, etc.The process utilizes a water-soluble film that contains the printed patterns. The film dissolves in the water and leaves the ink on the surface. In the typical process, the item to be printed is first coated with a primer or an adhesion promoter. After this dries, a base coat paint is applied to control the hue of the pattern.

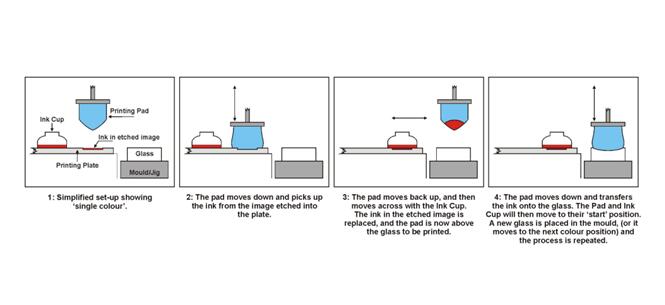

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on otherwise difficult to print on products in many industries including medical, automotive, promotional, apparel, and electronic objects, as well as appliances, sports equipment and toys.

Laser engraving technology is typically used to engrave metal workpieces that will be exposed to various types of wear or surface treatments. Metal engraving works with steel and aluminum (including anodized and die-casting aluminum).