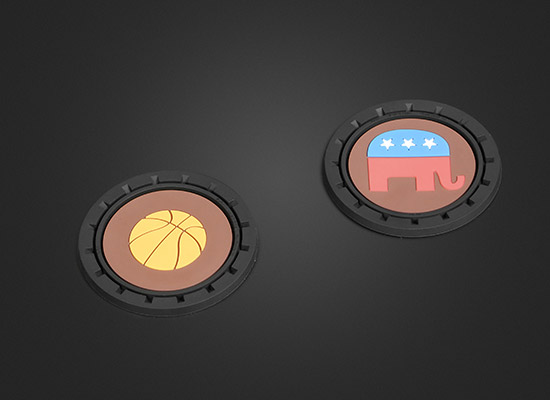

Production

Micro-injection of PVC

Process

1. Open the mold - Make the corresponding renderings according to the requirements, use computer engraving, and break the corresponding mold;

2. Toning - According to the pattern requirements, to achieve the required color and hardness;

3. Micro-injection - Automatic injection, according to the pattern that has been set. Then baked it and the product will be taken after cooling;

4. Quality inspection and trimming, each product must be free of bubbles, no trachoma, no color mixing, overall clean, and meticulous trimming of burrs to meet the standard.

Features

1. It can express any color in nature;

2. It has good corrosion resistance

3. The surface of the product can also be used for silk screen printing, pad printing, oil spraying or arbitrary graffiti;

4. The logo and pattern on the surface of the product can be made 3D stereo effect.